Humanity grasps more and more land such as roads, airports, etc.

But we can return those areas vertically to plants.

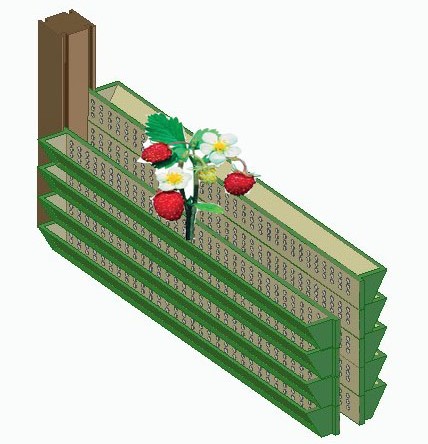

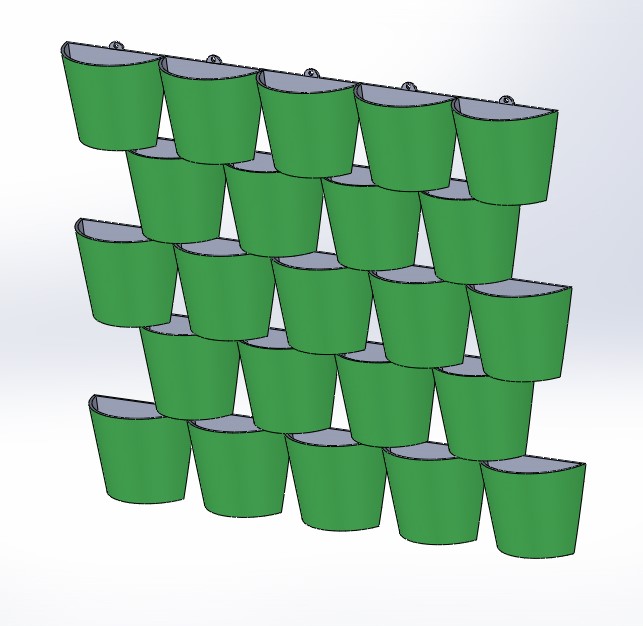

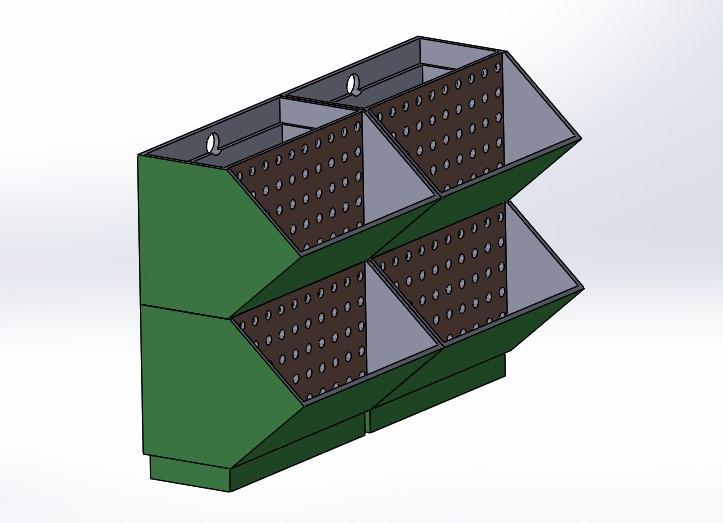

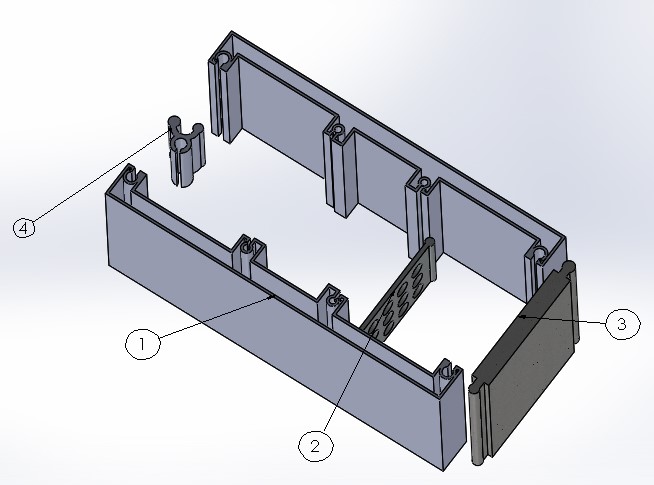

For this purpose it is necessary to build walls with special building blocks. These blocks are filled with an soil and arranged so that there is a space for plants between them.

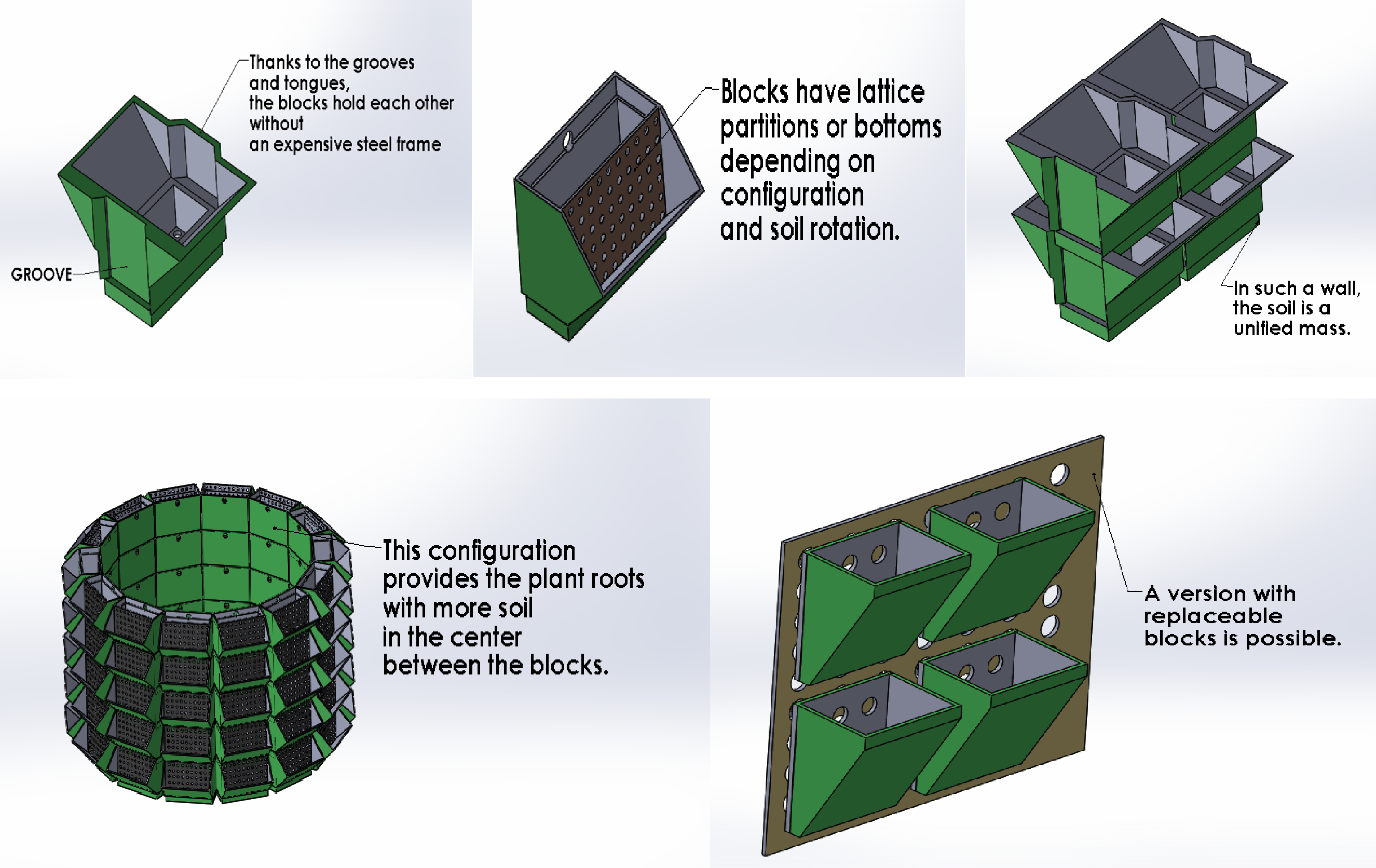

There are two variants of such masonry: longitudinal and cruciform:

Longitudinal blocks are particularly suitable for the construction of noise insulation walls along highways.

Blocks have openings in the bottoms in such a way that the soil of all the walls is a entire mass. It is very convenient for root system of plants and for irrigation.

In the event that this version is used for vertical gardens, then the blocks can be removable - for ease of operation.

Despite the simplicity and obviousness of the technology, it is regarded by international experts as an innovation. It won two international competitions - IDEANCO and Launch Fort Harvesting Challenge.

There are two innovative aspects here:

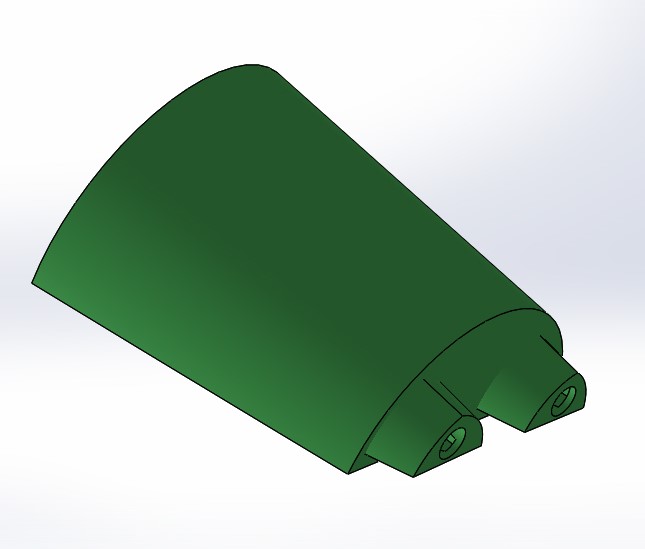

1. The blocks are shaped in such a way that they hold each other without an expensive steel frame. Therefore, the construction costs of this farm are at least 2-3 times less than that of a conventional vertical farm, because the steel frame makes up about half of the cost.

2. The shape of the blocks ensures the unity of the soil throughout the entire volume of the vertical farm. This allows you to grow not only greens and lettuce, but also those vegetables that are difficult to grow in conventional vertical hydroponics - eggplant, bell peppers, etc. Thus, the yield per square meter increases by 4-5 times, and, accordingly, the cost of heating greenhouses is also reduced.

These blocks can also be half-round, triangular - if you want the fence to be smoothed by the outside party.

More complex configurations are possible - for example, for the cladding of old walls, these "cubes" have the hemispherical shape.

They are fastened to a wall using dowels or steel cables.

Additional details are also provided. For example, the longitudinal blocks may not be too long, but assembled. This option simplifies production and transportation. Methods of assembly may be different depending on the design.

Тhese blocks themselves can be fully prefabricated from individual parts as well as the formwork described below.

Such collapsible units will be more attractive to customers of small lots.

Existing plastic pots for plants have no such ergonomic shape as to build green walls from them. These green blocks are more compact and stable.

One more variant of such blocks is possible.

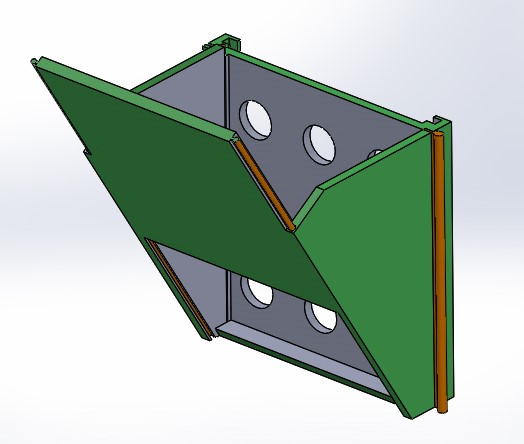

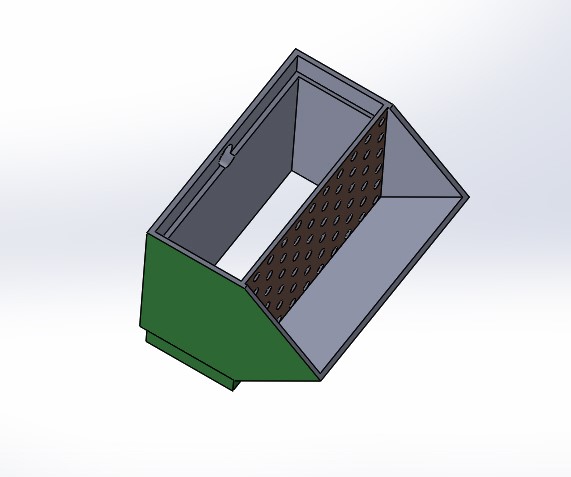

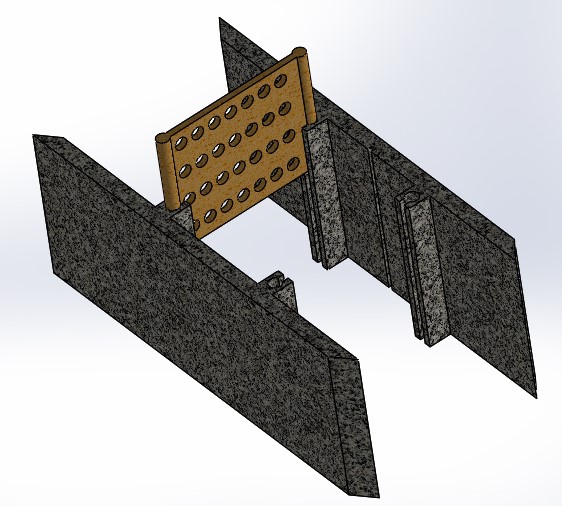

It differs from the existing ones in that it has a mesh partition that divides the unit into two chambers.

This partition is an innovation that is patented.

The first chambers create a single space that is filled with soil, and plants are planted in the second chambers.

Plants can develop roots throughout the wall, which makes them healthier and more resistant, since plants have a genetic need for larger roots.

Other green walls provide plants with only small pots with a small volume.

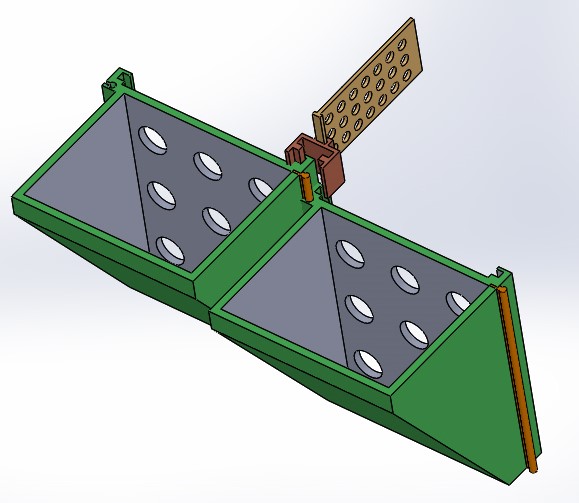

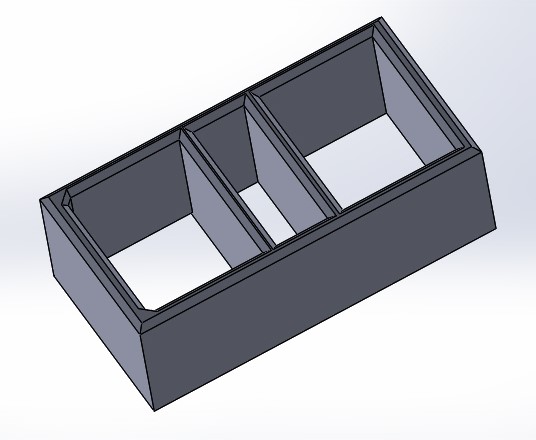

Made of plastic, it is possible to produce block formwork.

The fact is that the existing formwork blocks are made of very soft polystyrene.

Therefore, they require a great deal of care. They are very easy to break, smooth and do not allow the pouring of much concrete at the same time in many layers.

The blocks offered by us are made of solid plastic.

They are not massive - like the existing ones - which is very expensive and uneconomical.

They have thin walls and no bottoms.

They have partitions for durability and a thermal barrier coating is in the middle.

But when polystyrene concrete is poured into the block, this thermal layer is no longer needed.

The partitions have such a configuration that the block can easily be halved. The partitions have such a configuration that the block can easily be halved.

The walls of the blocks have grooves in the middle - for ease and accuracy when cutting in the middle.

These blocks have such ends and cuts that they are attached both longitudinally and transversely to each other so that they form a single empty space in the volume of the wall.

And when concrete is poured into this room, a wall is created that does not have to be plastered and painted. The desired color and texture are applied to the blocks during casting.

This saves building material and labor.

In addition, nature is freed from plastic waste. The demand for a building block is so great that even waste is not enough. As far as environmental friendliness is concerned, it has long been known that plastic waste is not toxic. They are recycled and used to make new bottles and packaging for food. So the block molds made of recycled plastic are not toxic, as are no bottles for mineral water.

In the production of blocks, only those plastics are used that are harmless to human health - mainly HDPE and PET. Other combinations are also possible with different manufacturing techniques - for example, the walls of the blocks of one material are hollow and they are filled with another type of plastic which has a lower thermal conductivity.

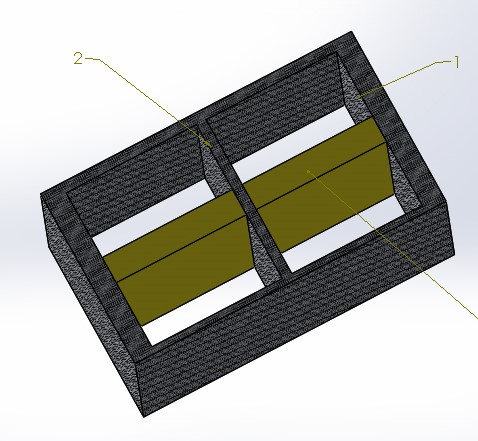

To reduce the thermal conductivity of the walls of blocks, you can use a pre-made configuration. In this embodiment, the block shape consists of separate elements which are connected by means of grooves and ribs of the corresponding molds.

The advantage of this configuration is that the block formwork has only one partition (made of metal or another material with low thermal conductivity) and the transverse sides are installed at the end of the wall. Throughout the wall, the sides of the block are connected with horseshoe-shaped elements. In these elements, transverse fastening can be located too.

It is possible to connect directly without additional elements, but this requires additional types of cross plates.

Thus, each block has only one "bridge" instead of four to transfer heat inward. This configuration saves the material. It is more convenient for transportation as it requires less space, etc.

These blocks reduce the cost of waterproofing by 90%, so they are ideal for building basements.

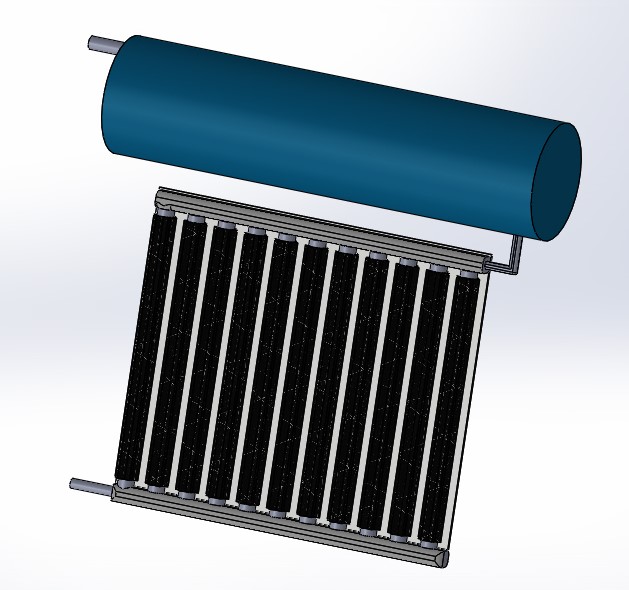

Simple Solar Water Heaters can also be produced from plastic waste.

Of course, they will not be as effective as vacuum tubes, but their advantage will be that they will have corrugated surfaces.

This will increase the amount of absorbed solar heat.

In addition, they will be cheaper and more accessible to the general public.

|